Silicon Pillar Formation

We are just starting a new project in the lab that will hopefully create a new method of creating silicon nanowires. But first we need to understand how to create ordered arrays of latex nanospheres on silicon surfaces. Carolyn Somerville has taken on that challenge and is now working to perfect a method of depositing an ordered monolayer of nanospheres on a silicon surface.

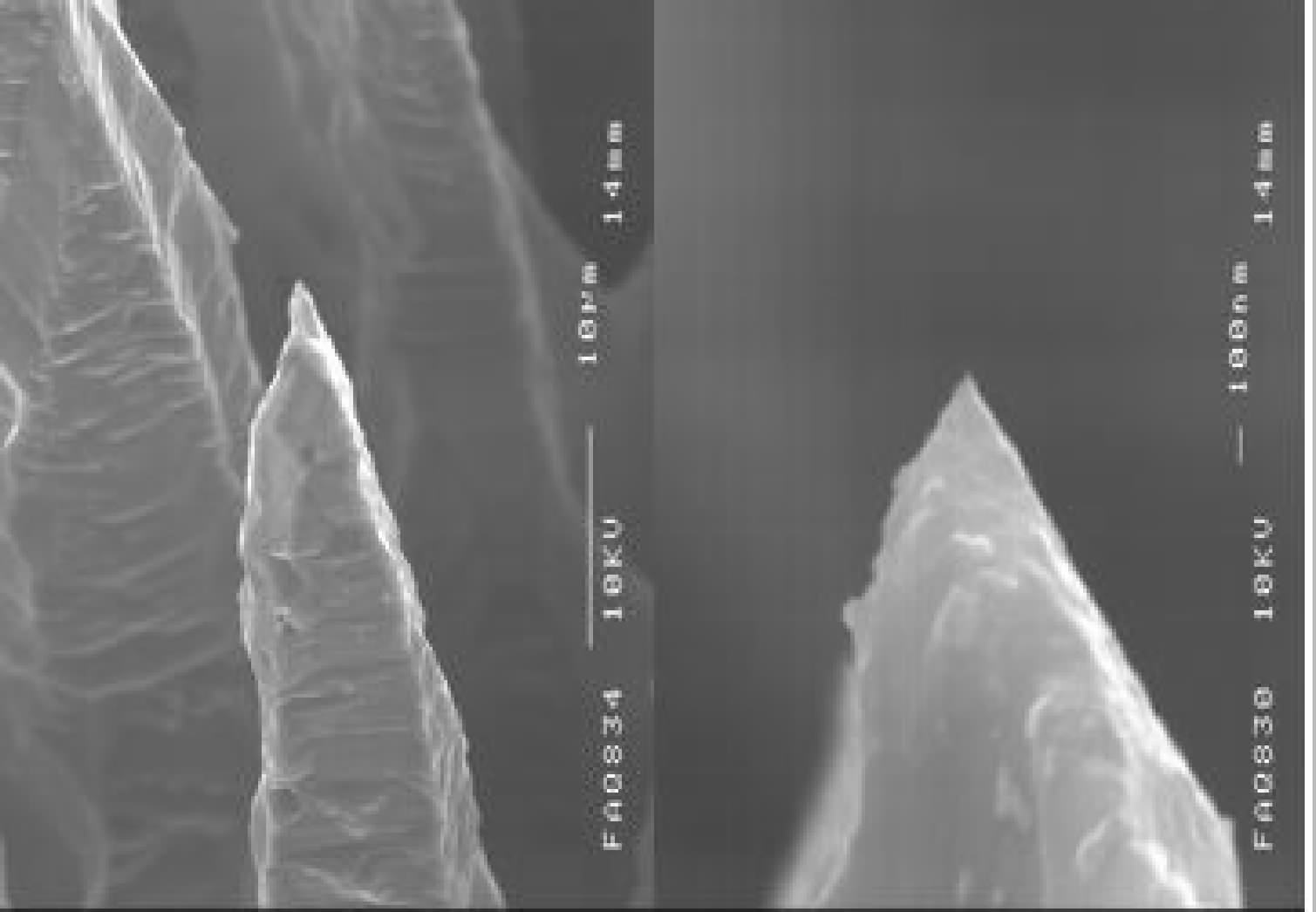

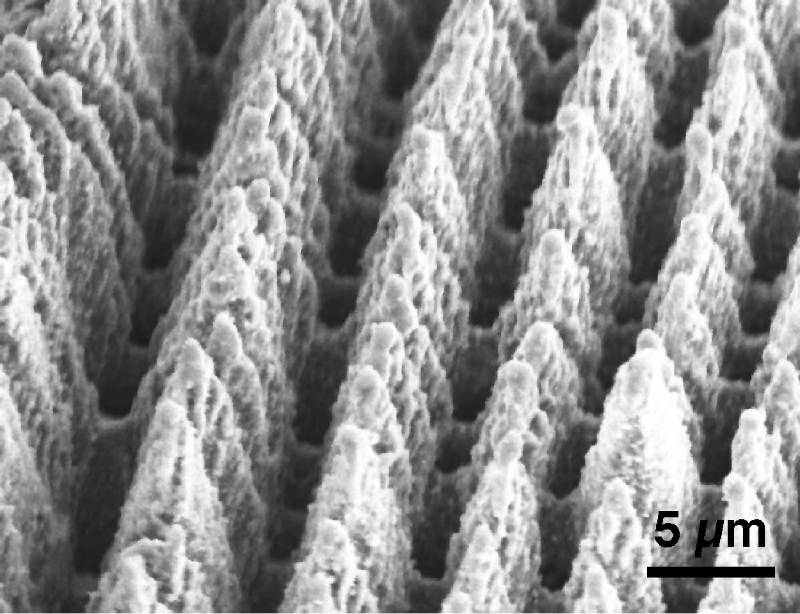

We have studied methods of pretreatment that lead to ordered arrays of pillars, as shown in the image on the right. Also post-irradiation chemical treatments can lead either to macro porous silicon (discussed more below) or sharpened pillars. As shown in the micrograph on the left, we have used KOH or TMAH etching of pillars to produce nanosharp pillars. In the best cases, we have obtained 10 nm tips on 100 µm tall pillars. These are perhaps the highest aspect ratio free-standing features ever made in silicon.

The mechanism that forms the pillars depends on the laser pulse duration. In the ultrafast regime (femtosecond laser pulses), an optical phenomena are responsible for setting up the length scale of the initial perturbation to the structure of the surface. These phenomena (diffraction and interference) lead to a spatial modulation of the laser's intensity profile. We intensionally modifed the profile (using diffraction to cause a sinusoidally varying intensity profile) to obtain control over the pillar formation process. This is how we made the aligned pillars shown above on the right.

When using nanosecond pulses, the length scale is longer. The pillars are larger and spaced further apart. This is because mechanical effects lead to a deeper broader initial modulation of the surface structure. A different optical phenomena then get involved in the pillar formation process. These phenomena relate to how light reflects off of the surface structure and the sides of the emerging pillars. A similar phenomenon has been observed to cause the formation of penitentes through the action of sunlight on snow in the Andes mountains. Penitentes are snow/ice pillars that form on glaciers and can reach heights of 1-4 m!

We have investigated the optical and chemical parameters that influence the growth and morphology of these pillar films, as well as their reflectivity. Pillar covered surfaces appear black as shown in the photo below.

We may also study the geometric and electronic structure of these films by means of scanning tunneling microscopl,Raman spectroscopy and electron microscopy, among other techniques.

In collaboration with Professor Mool Gupta, we worked toward improving the performance of devices such as solar cells and photodetectors by means of surface texturing. In collaboration with Professor Brian Helmke, we sought to understand how cell/surface interactions are influenced by surface texturing.

Macropore Formation

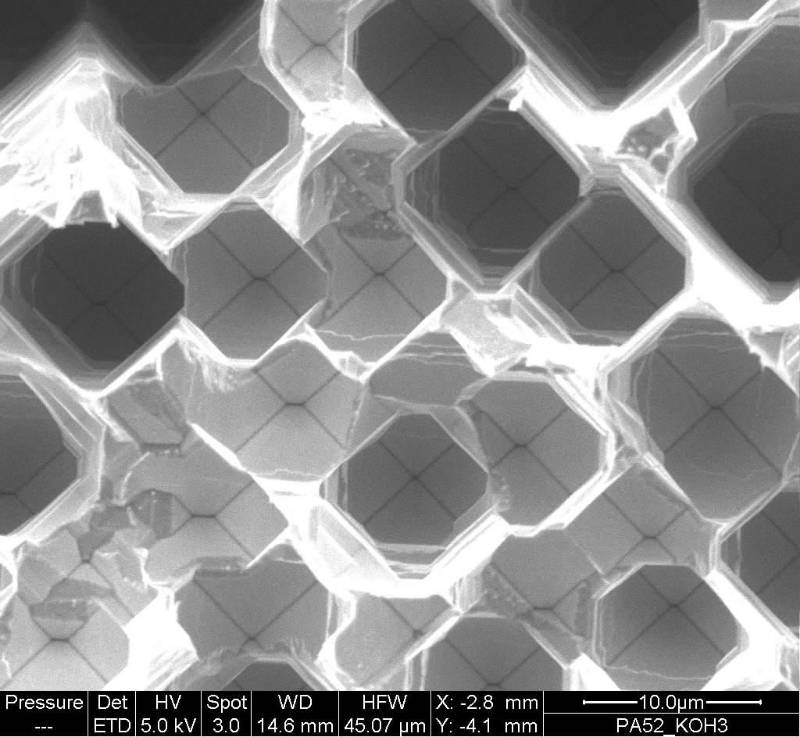

As mentioned above, over-etching the pillars leads to the formation of macropores. Dave Mills and I first started working on this back at Queen Mary in London. We found that macropores could be formed when pillars created by nanosecond laser irradiation were etched in hot aqueous KOH. Maggie Dudley performed some brilliant work etching pillar-covered substrates. In this case she etched pillars formed by femtosecond laser irradiation in either KOH or tetramethyl ammonium hydroxide (TMAH). Maggie's work on macropore formation has been published in the Journal of the Electrochemical Society .

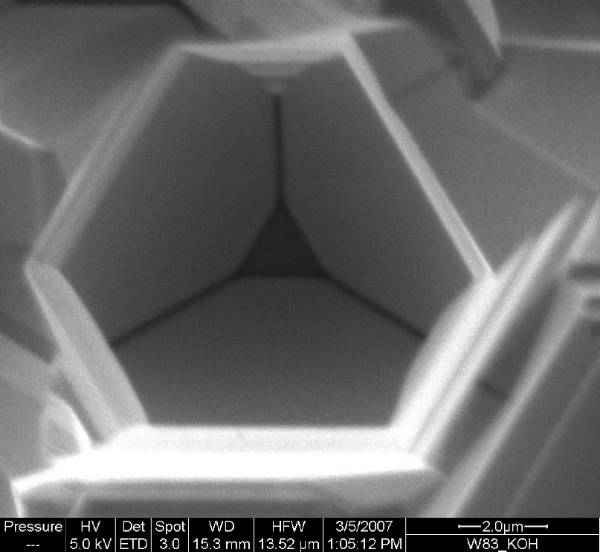

What has been quite interesting about this work is that we obtain crystallographically defined pores. Thus, we can get square, hexagonal or triangular pores based on how we etch sample and whether we choose Si(100) or Si(111) substrates. The (100) and (111) refer to specific crystallographic orientations of the plane that defines the surface of the silicon crystal. Different planes have different arrangements of atoms. These different arrangements affect not only the stability of the different planes but also the rate at which they are etched in KOH or TMAH solutions.