Success Starts Here - Brandon Barker

WCU Cultivates Leaders, Thinkers & Doers

WCU Junior Produces 3D Protective Gear for Frontline Workers

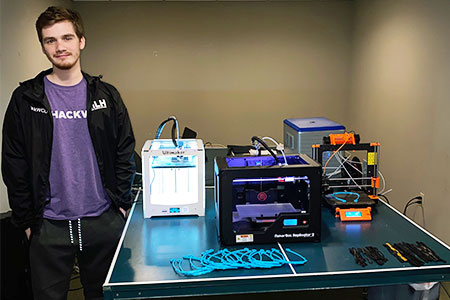

Brandon Barker with the 3D printers he uses to make PPE.

T

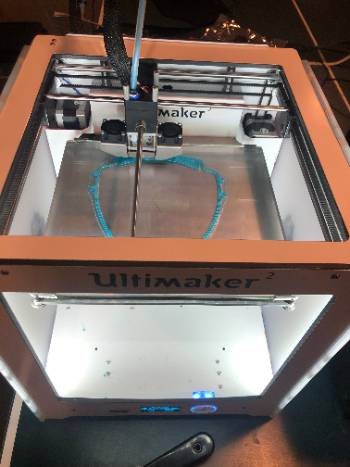

wenty or more hours a day, seven days a week, 3D printers in Brandon Barker’s Downingtown, Pa., basement churn out plastic shields that can help prevent the spread of COVID-19 when worn alone or in conjunction with a face mask.

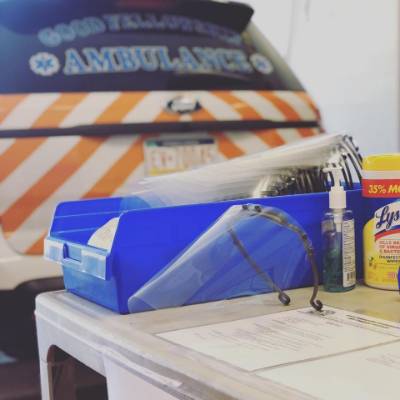

Barker, a West Chester University junior, is working in conjunction with other members of Out of the Box Robotics, a nonprofit organization he helped establish while still in high school. Collectively, club members have donated more than 1,100 face shields to frontline workers at such organizations as the Minquas Fire Company No. 2 in Downingtown, the Westwood Fire Company in Coatesville, and the Good Fellowship Ambulance & EMS Training Institute in West Chester.

They also have created more than 800 tension reliever bands. These bands allow for a face mask to be fastened around the head, rather than looped over the ears, to increase comfort and prevent pressure ulcers.

Barker was given permission to use a West Chester University 3D printer as well as raw materials from the iNOV8 makerspace in the Frances Harvey Green Library. The iNOV8 makerspace is an area set aside for collaborative, creative work using high tech to no tech tools. Christian Penny, a professor of Educational Foundations & Policy Studies, coordinated the temporary loan and retrieval of this 3D printer, in conjunction with WCU’s Department of Public Safety. Penny has worked with Barker previously on various 3D projects in the makerspace.

"Brandon is an incredibly driven and hard-working student. As soon as I met him, I was taken back by how impatient he is. I mean that in the most positive sense,” says Penny. “He’s not waiting for someone else to take the initiative. He’s out in front generating change, innovating and problem solving."

Penny also was given permission to borrow another University-owned 3D printer, which, while too small for face shields, is perfect for making tension reliever bands. Penny and his three sons are printing the bands for first responders and health care workers, including Penny’s wife, Heather, a physician assistant in Jennersville, Pa. To date they have printed and delivered more than 250 bands to essential workers.

Barker primarily focuses on making face shields, which take 45 minutes to print. As soon as one face shield is finished, Barker queues up the printer for a new one. A self-professed night owl, he keeps the printer going from dinnertime until 3 a.m. or 4 a.m., while his dad, Bill Barker, usually handles operations during the day. Barker’s mother, WCU assistant professor of nursing Nancy Barker, also served a critical role, providing input into template designs.

"There are a lot of open source designs for face shields but not all are ideal,” says Barker. “My mom helped choose a design that is higher impact relative to the needs of the people who will use them."

Barker gives a lot of thought to the end user, which he is why he conducts quality control on every shield that comes off the printer. "Sometimes I need to sand rough edges down; stuff like that," he says. He also is quick to deflect praise. "I’m not doing anything special," he says. "The real heroes are the doctors, nurses and others who are putting themselves at immense risk to help others."

A double major in computer science and business administration with a minor in mathematics, Barker is active in the University’s Computer Science Club. He helped created HackWCU, an annual event that is part of an international coding marathon. He already has completed six internships – his first while still in high school. This summer he will be interning with California-based Uber, remotely from Chester County. Long-term, Barker says he’d like to be the chief technology officer or CEO of a technology company and develop technological innovations that advance society.

Right now, though, Barker has his eye focused on more immediate societal needs – the 3D printer gently rumbling in his basement is almost ready for an infusion of new plastic, and a batch of face shields is waiting to be boxed up and delivered to the frontline workers who need them.

How You Can Help

Donate

There’s a waiting list of frontline workers interested in receiving face shields and/or tension reliever bands from Brandon Barker and other members of Out of the Box Robotics. It takes time to make these items but it also takes raw materials, which have increased dramatically in price in recent weeks.

As a 501(c)(3) nonprofit, Out of the Box Robotics accepts tax-deductible contributions to offset the cost of these materials.

Donations can be sent to:

Out of the Box Robotics

20 N. Bailey Rd.

Suite 72203

Thorndale, PA 19372

Write “COVID-19 response” in the memo line of your check. Checks only; no cash or credit card donations, please. For more information about Out of the Box Robotics, email ftc7244@gmail.com.

Make PPE

If you own or have access to a 3D printer, Barker suggests checking out these design templates and other resources, for making personal protective equipment. There are even templates for making devices that can be used to avoid touching surfaces that could be contaminated.

Liam, Chris and Keagan Penny with raw materials and a 3D printer for making PPE. Photographer Conner Penny.